OUR QUALITY PROCESS

Achieving optimum quality involves selecting the best raw materials, specific equipment and many steps for each grain. Thus, our entire quality approach aims to ensure the best value for money.

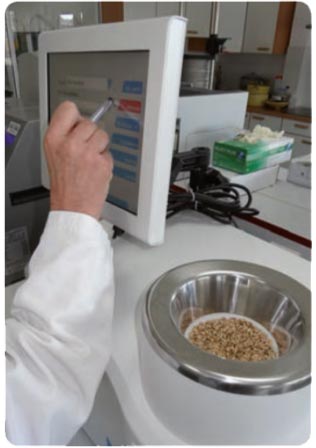

Each batch of raw material is thus analyzed upon receipt.

MONITORING PLAN OF RAW MATERIALS

2.Tests (External Lab)

Ad hoc tests

Find out more

- Mycotoxins (Aflatoxins B1, B2, G1, G2; ochratoxin A; DON, ; zearalenone)

- Heavy metals

Systematic tests

Find out more

- Organo phosphorus and Organo chlorinated pesticide residues

- GMO on Soy, basmati rice, on Thai rice, on brown flax

- Radioactivity on all products from Japan

3.Internal Controls (Celnat Lab)

PHYSICO-CHEMICAL

Find out more

- Humidity

- Density (PS)

- Dehulling test (oats, barley, rice)

- Mycotoxin DON on wheat, barley, oats

- Germination rate

ORGANOLEPTIC

Find out more

- Color, smell, appearance

- Small grains

- Rates of impurities

- Pest research

- Disease (ergot, decay)

COMPLEMENTARY TESTS

ON WHEAT

Find out more

- Protein

- W (Bread quality)

- Hagberg (Bread quality)

Monitoring the quality of our in-process and finished products is based on the HACCP method applied by an experienced team

MONITOR IMPURITY CONTENTS

LABORATORY TECHNICIAN

DETERMINATION OF PROTEIN RATIOS

ANALYSIS OF THE BAKING PROPERTIES

QUALITY ASSISTANT